The City of Hamilton has approximately 130 stormwater management facilities (SWMFs) that detain runoff, slowing down the flow and erosive forces of water, thus allowing sediment to settle before releasing water into the downstream environment at a pace that tries to mimic the hydrology of an undisturbed natural forested landscape. These facilities include approximately 70 wet ponds and wetlands, which hold a permanent pool of water and settle out sediment from incoming runoff through its water column. The city surveys these facilities on a three-year cycle for sediment accumulation and monitors surface water quality within its watersheds, two key indicators of the effective performance of these stormwater facilities.

The city follows industry best practices to dredge a stormwater pond when it reaches 50% of its holding capacity, removing the accumulated sediment to restore the designed treatment capacity of a SWMF. Forecasting and planning are done annually with $2.5 million per year allocated for annual dredging works. Changing regulations, and overall system growth driven by new development and climate change adaptation initiatives, may affect this budget, which has Hamilton Water taking a closer look at the efficacy of their current program.

Strengthening regulations

The municipal Consolidated Linear Infrastructure Environmental Compliance Approval (CLI-ECA) replaces the numerous individual Environmental Compliance Approvals (ECAs) that were previously issued for the various components of municipal sewage collection systems and each stormwater management facility. One of the ramifications of the CLI-ECA for municipal stormwater systems is that there will be a new approach to the overall system oversight imposing a consistent set of conditions intended to improve environmental protection including a higher focus on operation and maintenance activities, performance measurement and mandating the development of monitoring programs as required in the conditions of the CLI-ECA.

Drawback of the current method

The current sediment survey method requires two city personnel to manually survey the ponds from the water, which involves loading a boat onto a large vehicle and then launching it into ponds across the city to collect depth measurements. Some of the facilities are harder to access due to limited workspace off the roadside of a busy highway, such as the Red Hill Valley Parkway ponds, making the task arduous with an element of risk. The work is time consuming, requires safe work practices for working in and around water, and staff must contend with steep or slippery bank slopes, heavy equipment, and the potential for changing water and weather conditions.

In addition, the current methodology for sediment surveying has some limitations that can affect accuracy. City personnel obtain depth measurements by using a surveyor’s GPS receiver placed on an extended range pole to measure the elevation of the sediment in 10 locations across the facility. Overgrowth of submerged vegetation can create a falsely high elevation of the pond base, but the plate at the bottom of the survey rod can also compress sediment for a deeper measurement than intended. Windy conditions can also cause the boat to drift, reducing the ability to pinpoint a specific location within the pond to take a measurement.

The average sediment depth of the 10 locations is compared as a percentage of the design water depth of the facility. The difference between the designed depth and the current depth in these areas is used to estimate the level of existing sediment across the basin of the facility, thereby estimating the actual volume. The surveys completed in 2022 provided sediment volume estimates that were higher than the actual quantities of sediment removed from the ponds during dredging.

However, in many cases, sediment settles in some areas more than others, meaning part of the pond may still have the capacity to accumulate sediment, and the pond could continue to treat water quality effectively for a longer period, so dredging may not be necessary right away. As this data is used to determine the best time to dredge a stormwater management pond asset, knowing when to intervene can ensure value for money for the Hamilton taxpayer.

“With more stringent regulations on the horizon, it is a good time to evaluate current methodologies and look at new technologies, and also see what other municipalities are doing to improve management of stormwater facilities,” Don Young, water distribution and wastewater collection manager for Hamilton Water, said.

Partnering with the local college

Fortuitously, a Hamilton Water employee, Amanda Wong, found out that the Unmanned and Remote Sensing Innovation Centre (URSIC) at Mohawk College was looking to test its new drone technology.

“The URSIC needed to test their cutting-edge remote sensing technology that collects high quality data to visualize critical infrastructure, and our local storm ponds provide the perfect testing environment being small bodies of water with known design parameters. So, we discussed a partnership to do exactly that,” said Wong, a stormwater management technologist at Hamilton Water.

Young continued: “These programs are a win-win for both parties as students get to put their new discoveries to the test, and we can evaluate the impact of these innovations and ideally improve processes that positively impact the citizens and environment of Hamilton.”

The URSIC program is funded by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Drone-mounted sonar

The URSIC team worked with the City of Hamilton’s Stormwater Operations and Maintenance Team to test new drone-mounted bathymetric equipment for estimating the existing sediment levels at SWMF. The city selected a variety of ponds to challenge the cutting-edge sonar equipment by including large, small, heavily vegetated and isolated sites with poor satellite signal.

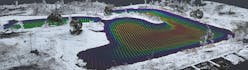

A flight plan was developed for each pond, from a ground control station using Universal Ground Control software (UgCS) to follow flight paths distributed across the surface of the SWMF in a grid. The team then flew a DJI M300 RTK drone across the facility, collecting sound measurements using the Echologger ECT 400S single-beam sonar. The sonar device is suspended below the water’s surface, from a drone flown approximately 2m above the water surface (held in position with the radar altimeter). The depth soundings are geolocated with the real-time kinetic (RTK) global navigation satellite system (GNSS) positioning on the drone.

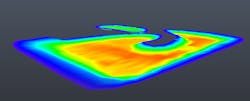

Processing of the sonar data is done by Hydromagic software producing a 3D model of the SWMF bottom and the volume of water above. The addition of a second drone for photogrammetry has the added benefit of capturing a 3D model of the site above the water level too.

“The Drone mounted sonar presented several challenges, so our students worked together with the City of Hamilton team, trying different approaches until we were confident that we had the most accurate volumetric data for the SWMF that we set out to measure,” Matthew Shelley, professor of building and construction sciences at Mohawk College said. “We are fortunate to have a very good URSIC team that is especially skilled at adopting and adapting new technology to meet the desired outcome.”

Results

While this project is still ongoing, results have been excellent so far. Instead of estimating the facility’s capacity based on ten measurements, this technology provides a mapping of SWMF in high resolution and allows for highly accurate calculations of existing storage capacity. This level of accuracy removes the guesswork from SWMF maintenance schedules. It also protects the natural ecosystem of each SWMF and saves money by avoiding maintenance investment too early.

“The problem that slowed us down in phase 1 with flight programming is now resolved. A trained crew doing this work in the future would likely be able to do 3-4 SWMF a day depending on the size of the facility,” Shelley said.

The URSIC measured 2-3 facilities a day, while constantly training student employees and showcasing the technology.

“A more robust process and data collection strategy will ensure we are dredging at the optimal time and using drones to take measurements instead of mobilizing large equipment will save time and money as well as mitigate safety issues that can arise when crews are working on water,” said Young. “Thanks to the URSIC team at Mohawk College and the brilliant technology from SPH Engineering we are impressed with the results.”

In terms of a long-term plan, the city plans to evaluate more technology solutions to find the most viable, safe, and affordable way to measure and maintain its SWMF and stay in compliance with the new regulations.